Gundlach Crushers – Unique characteristics of cage mills expand applicability across mining operations

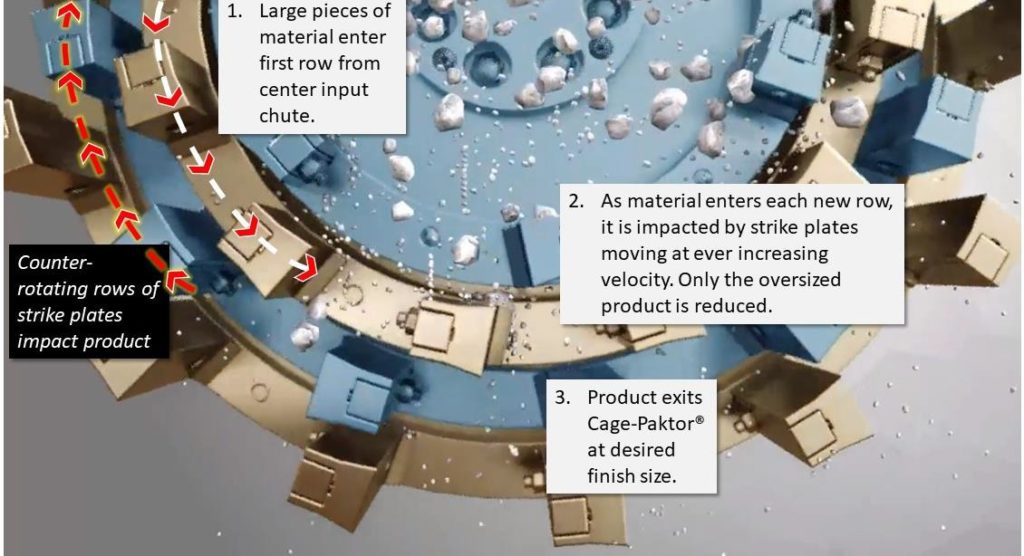

Cage-Paktor allows:

- Reduced fines

- Lower maintenance

- Smaller product sizing

Configurations:

- 1-2 independently moving cages

- From 3 to 6 rows

Advantages:

- Less susceptibility to plugging for wet or sticky material

- High yields with minimal fines: typically with 95+% yield of product top size while creating minimal fines

- Longer production of consistent product sizes: With cage mills, product size stays constant over the life of its wear elements, as opposed to other crushers that produce variable product sizing as components such as hammers and breaker blocks wear down

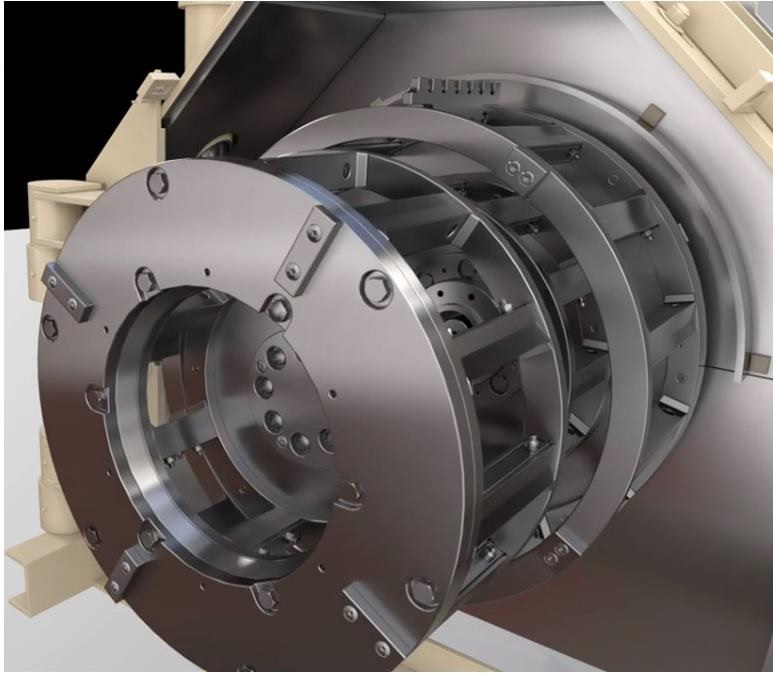

Design advantages of Cage-Paktors versus traditional cage mills:

- Flat face design

- Elimination of weld-on liners and introduction of thicker, stronger, more wear resistant components

- Improved striking plate design: the new striking plate designs of Cage-Paktors offer two distinct advantages: preventing plate ends from cracking or snapping off and minimizing wear on side rings

- Backward compatibility: the updated array of cages and striking plates are seamlessly interchangeable with older Cage-Paktor models

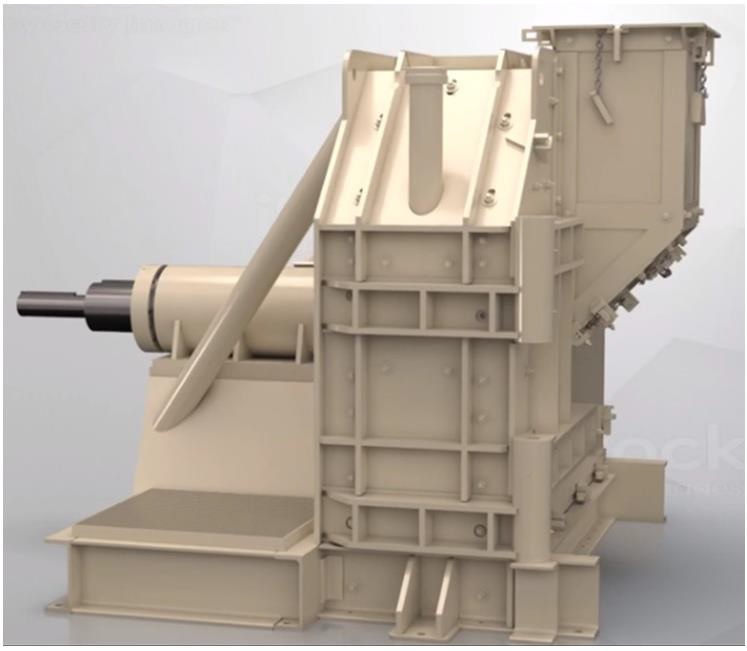

For many materials, the Cage-Paktor can effectively size material in the 150 – 1000 μm (20 – 100 mesh) range at a high efficiency (percentage passing), a very attractive capability for many operations, especially when considered alongside the machine’s minimal footprint, low install cost, and reduced long-term maintenance requirements.

For further information do not hesitate to contact us.