Euragglo – Granupaktor

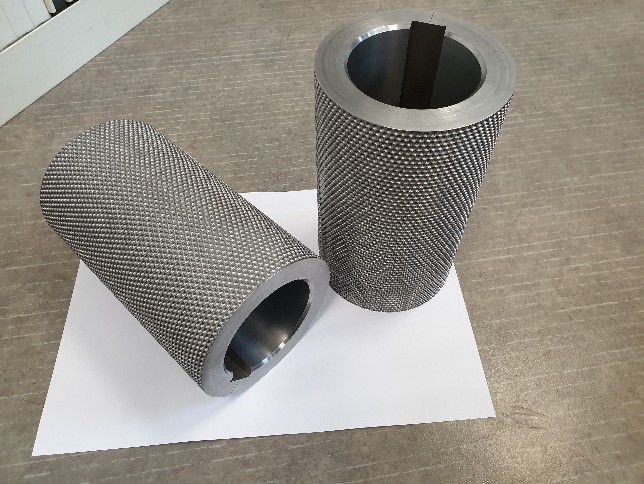

Granupaktor is a special machine for the direct production of granules from various raw materials, including fertilizers and salt, using roller-press technology.

This process is a simple alternative to existing dry and wet granulation processes, but avoids the addition of complementary machinery, decreasing CAPEX and substantially reducing OPEX (energy…).

Here are the main advantages compared to traditional processes:

- Regular shape of granules

- Optimized granulation efficiency

- Simplified production circuits

- Low investment costs compared to granulation or wet compaction

- Easy maintenance

- Low energy consumption per ton

Numerous applications have been tested in our laboratory, for example those most tested are:

- Fertilizers: ammonium sulphate, NPK, PK, various NP formulations

- Salts: sodium chloride and other soluble salts

The granules have a diameter of about 5 mm and are uniform, similar to the round granules produced by wet granulation.

Depending on the nature and bulk density of the product, the flow rate is between 1,8 and 3 t/h.

Please note that we have a Test Center in Quiévrechain, France, where we can perform feasibility tests on Granupaktor and the classic compaction-granulation process. In addition, we can offer rental service for Granupaktor and all other presses and compactors.